Product Description

|

item |

value |

|

Warranty |

1 year |

|

Applicable Industries |

Manufacturing Plant, Construction works , Energy & Mining, Other |

|

Customized support |

OEM |

|

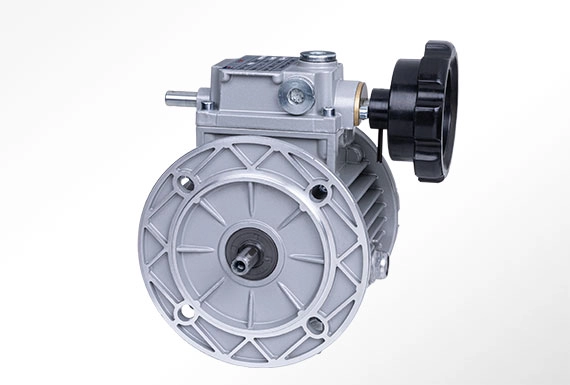

Gearing Arrangement |

Worm |

|

Place of CHINAMFG |

ZheJiang , China |

|

Input speed |

1500 |

|

Output speed |

1.3-193rpm |

|

Product name |

Udl Variable Speed |

|

MOQ |

10pcs |

|

Color |

Customization |

FAQ

Q1:Are you a manufacturer or trading company?

Yes, We are a leading manufacturer specialized in production of various kinds of small and medium-sized

motor.

Q2:How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q3:What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor information etc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

Q4:What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry, escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

Q5:How about your delivery time?

For micro brush dc gear motor, the sample delivery time is 2-5 days, bulk delivery time is about 15-20 days, depends on the order qty. For brushless dc motor, the sample deliver time is about 10-15 days; bulk time is 15-20 days.Please take the sales confirmation for final reference.

Q6:What’s your warranty terms?

One year

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | as for Request |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Stepless |

| Samples: |

US$ 65/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended for variators to ensure optimal performance?

To ensure optimal performance and longevity of variators, certain maintenance practices are recommended. These practices focus on regular inspections, proper lubrication, and adherence to manufacturer guidelines. Here’s a detailed explanation of the maintenance practices recommended for variators:

1. Regular Inspections:

Regular inspections are essential to identify any signs of wear, damage, or abnormal operation in variators. Inspect variators visually for leaks, loose fasteners, or any visible damage. Pay attention to abnormal noises, vibrations, or changes in performance, as these could indicate potential issues. Regular inspections allow for early detection and timely resolution of problems, preventing further damage and ensuring optimal performance of variators.

2. Lubrication:

Proper lubrication is crucial for the smooth operation and longevity of variators. Follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricants. Ensure that the variator is well lubricated, paying attention to the bearings, gears, and other moving parts. Insufficient lubrication can lead to increased friction, wear, and heat generation, compromising the performance and lifespan of variators. Regularly check the lubricant levels and top up or replace the lubricant as per the manufacturer’s specifications.

3. Cleaning and Debris Removal:

Keep variators clean and free from debris, dirt, and contaminants. Regularly inspect and clean the variator housing, cooling fins, and vents to ensure proper airflow and cooling. Remove any debris or foreign objects that may have entered the variator and could interfere with its operation. Accumulated debris can impede heat dissipation and interrupt the smooth movement of components, affecting the performance and reliability of variators.

4. Belt/Chain Inspection and Adjustment:

If the variator is part of a belt or chain-driven transmission system, it’s important to inspect and maintain the belts or chains. Check for signs of wear, damage, or improper tension. Replace worn or damaged belts or chains promptly, and ensure proper tension according to the manufacturer’s specifications. Incorrect belt/chain tension can lead to slippage, reduced power transmission efficiency, and premature wear on variators. Regular inspection and adjustment of belts or chains contribute to optimal performance and longevity of variators.

5. Temperature Monitoring:

Monitor the operating temperature of variators regularly. Excessive heat can be detrimental to variator performance and lifespan. Ensure that variators are operating within the recommended temperature range specified by the manufacturer. If the operating temperature exceeds the acceptable limits, investigate and address the underlying causes such as insufficient cooling, excessive friction, or overloading. Proper temperature management helps to prevent overheating, component degradation, and premature failure of variators.

6. Adherence to Manufacturer Guidelines:

Follow the maintenance guidelines provided by the variator manufacturer. Manufacturers often provide specific maintenance schedules, procedures, and recommendations for their variator models. Adhere to these guidelines regarding inspections, lubrication, cleaning, and any other maintenance requirements. Manufacturers’ guidelines are based on extensive testing and expertise, ensuring that the variators perform optimally and have a longer service life when proper maintenance practices are followed.

7. Professional Servicing:

For complex maintenance tasks or major repairs, it is advisable to seek professional servicing from authorized technicians or service centers. Trained professionals have the expertise, tools, and knowledge to perform intricate maintenance procedures and troubleshoot variator issues effectively. Professional servicing can help identify and address potential problems before they escalate, ensuring optimal performance and reliability of variators.

By following these maintenance practices, variators can maintain their optimal performance, efficiency, and lifespan. Regular inspections, proper lubrication, cleaning, belt/chain maintenance, temperature monitoring, adherence to manufacturer guidelines, and professional servicing all contribute to maximizing the performance and longevity of variators.

What are the signs that indicate a need for variator repairs, and how can they be diagnosed?

Recognizing the signs that indicate a need for variator repairs is crucial for maintaining the performance and reliability of the system. Here are some common signs to watch out for and the diagnostic methods used to identify variator issues:

1. Abnormal Noise:

If you notice unusual noises coming from the variator, such as grinding, whining, or rattling sounds, it could indicate a problem. These noises may be a result of worn-out bearings, misaligned components, or damaged pulleys. To diagnose the issue, a thorough inspection of the variator, including the pulleys, belts, and bearings, can help identify the source of the noise.

2. Slipping or Inconsistent Power Transfer:

If you experience a loss of power or notice the engine revving without a corresponding increase in speed, it could indicate slipping belts or worn-out pulleys in the variator system. Inconsistent power transfer can also manifest as jerky acceleration or a delay in power delivery. Diagnosing this issue involves checking the tension and condition of the belts, as well as inspecting the pulleys for signs of wear or damage.

3. Overheating:

If the variator system becomes excessively hot during operation, it may indicate a problem. Overheating can be caused by factors such as insufficient lubrication, misalignment, or excessive friction within the variator components. Diagnosing this issue involves monitoring the temperature of the variator during operation and inspecting the lubrication levels, cooling systems, and components for any abnormalities.

4. Vibration or Shaking:

Excessive vibration or shaking during variator operation can be a sign of misaligned components, worn-out bearings, or damaged pulleys. These issues can lead to an imbalanced operation, resulting in vibrations felt throughout the machinery. To diagnose this issue, a visual inspection of the variator components and a check for any signs of wear or damage can help identify the source of the vibration.

5. Leaking Fluid:

If you notice fluid leaks around the variator system, it could indicate a problem with seals or gaskets. Leaking fluid can lead to inadequate lubrication or loss of hydraulic pressure, affecting the performance and reliability of the variator. Diagnosing this issue involves identifying the source of the leak and examining the seals, gaskets, and fluid levels for any signs of damage or wear.

6. Erratic Gear Shifting:

If the variator system exhibits erratic or inconsistent gear shifting, such as sudden jumps in gear ratio or difficulty in engaging certain gears, it may indicate a problem with the variator components or the control system. Diagnosing this issue involves inspecting the variator components, including the pulleys, belts, and control mechanisms, and checking for any misalignments, wear, or malfunctions.

7. Diagnostic Tools and Professional Inspection:

In addition to the visual inspections mentioned above, professional diagnosis of variator issues often involves the use of specialized diagnostic tools and equipment. These tools can include belt tension gauges, laser alignment devices, vibration analyzers, temperature sensors, and diagnostic software. Professional technicians with expertise in variator systems can perform comprehensive inspections and use these tools to diagnose specific problems accurately.

It’s important to note that variator repairs should be carried out by trained professionals with experience in variator systems. If you notice any signs indicating potential variator issues, it is advisable to have the system inspected and repaired by a qualified technician to ensure proper diagnosis and appropriate repairs are performed.

Can you describe the benefits of using a variator in terms of efficiency and performance?

Using a variator in various applications can offer significant benefits in terms of efficiency and performance. The ability to continuously adjust the gear ratio and optimize engine RPM contributes to improved fuel economy, smoother power delivery, and enhanced overall performance. Here’s a detailed explanation of the benefits of using a variator:

1. Improved Fuel Efficiency:

A variator allows for precise control of the gear ratio, enabling the engine to operate within its optimal RPM range. By continuously adjusting the gear ratio to match the driving conditions, the engine can maintain an efficient power output. This optimized engine RPM helps to reduce fuel consumption and improve overall fuel efficiency. Variators are particularly beneficial in situations that involve frequent speed changes or stop-and-go traffic, where traditional gear systems may be less efficient.

2. Smoother Power Delivery:

Traditional gear systems have discrete gear ratios, resulting in noticeable gear shifts when changing gears. In contrast, a variator provides stepless gear shifts, allowing for a smooth and seamless power delivery. The continuous adjustment of the gear ratio ensures that the engine operates at the most suitable RPM for the current driving conditions, resulting in a smoother acceleration and a more refined driving experience.

3. Optimal Performance:

A variator enables the engine to operate within its optimal power band. By continuously varying the gear ratio, the variator keeps the engine RPM at an ideal level, maximizing power output and torque delivery. This translates into improved performance, whether it’s for quick acceleration, high-speed cruising, or towing heavy loads. The ability to maintain optimal performance across a wide range of driving conditions is a significant advantage of using a variator.

4. Adaptability to Driving Conditions:

A variator allows for seamless adaptation to different driving conditions. It can adjust the gear ratio based on factors such as vehicle speed, throttle input, and load requirements. This adaptability ensures that the engine operates efficiently and delivers the appropriate power for specific driving situations. Whether it’s accelerating from a standstill, maintaining a constant speed, or climbing steep inclines, the variator can optimize the gear ratio to suit the demands of the moment.

5. Reduced Wear and Tear:

Due to the smooth and continuous power delivery, variators help to reduce wear and tear on various components of the drivetrain. The absence of abrupt gear shifts and the ability to maintain optimal engine RPM contribute to reduced stress on the engine, transmission, and other driveline components. This can result in increased longevity and reliability of the vehicle or machinery.

6. Enhanced Driving Comfort:

The smooth and seamless power delivery provided by a variator contributes to enhanced driving comfort. The absence of gear shifts and the ability to maintain the engine RPM in the optimal range reduce vibrations, noise, and harshness. This leads to a more refined and enjoyable driving experience, particularly in urban driving conditions or during long-distance journeys.

In summary, using a variator in various applications offers benefits in terms of improved fuel efficiency, smoother power delivery, optimal performance, adaptability to driving conditions, reduced wear and tear, and enhanced driving comfort. These advantages make variators a desirable choice for achieving greater efficiency and performance in vehicles and machinery.

editor by CX 2024-01-24