Product Description

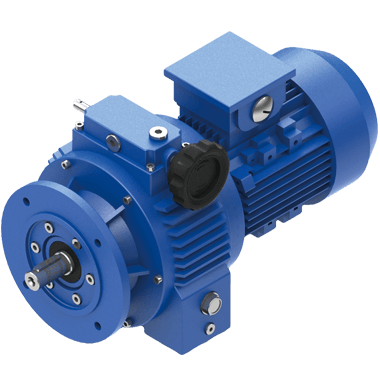

JWB Series Speed Variator

1. Features:

JWB-X type

- Sizes: ≥04

- Power up to 1.5 kW or more

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2-10r/min;4.7-23.5r/min;15-75r/min;20-100r/min, 28-140r/min, 30-150r/min;40-200r/min;60-300r/min;80-400r/min;100-500r/min;190-950r/min.

- Output Torque value max 1002Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

JWB-X B type

- Sizes:01,02,03 and 04

- Power up to 1.5 kW or less

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2r/min-20r/min;4.7r/min-23.5r/min;6.5-32.5r/min, 8-40r/min, 9-45r/min, 13-65r/min, 15r/min-75r/min;18-90r/min, 25-125r/min, 28r/min-140r/min;40r/min-200r/min;60r/min-300r/min;80r/min-400r/min;100r/min-500r/min;190r/min-950r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

2. Technical parameters

| Type | Output Torque | Output Shaft Dia. | Output Speed Range | 2rpm-950rpm | |

| SWB01 | 2.6-1.6N.m | φ11 | Applicable Motor Power | 0.18kW-7.5kW | |

| SWB02 | 258-1.8N.m | φ14,φ24,φ28,φ32 | |||

| SWB03 | 426-4N.m | φ24,φ28,φ38 | Input Options | With Inline AC Motor | |

| SWB04 | 795-8N.m | φ28,φ38,φ42 | With IEC Motor | ||

| SWB05 | 535-16N.m | φ38,φ48,φ55 | With Input Shaft | ||

| SWB06 | 1002-40N.m | φ42,φ55,φ70 | With Input Flange | ||

About Us

ZheJiang CHINAMFG Drive Co.,Ltd,the predecessor was a state-owned military mould enterprise, was established in 1965. CHINAMFG specializes in the complete power transmission solution for high-end equipment manufacturing industries based on the aim of “Platform Product, Application Design and Professional Service”.

CHINAMFG have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend;

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

product is a product inspection to determine the qualified products.

7. Certification.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery, Ceramic |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical or Horizotal Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary Conedisk Friction Type |

| Step: | Stepless |

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended for variators to ensure optimal performance?

To ensure optimal performance and longevity of variators, certain maintenance practices are recommended. These practices focus on regular inspections, proper lubrication, and adherence to manufacturer guidelines. Here’s a detailed explanation of the maintenance practices recommended for variators:

1. Regular Inspections:

Regular inspections are essential to identify any signs of wear, damage, or abnormal operation in variators. Inspect variators visually for leaks, loose fasteners, or any visible damage. Pay attention to abnormal noises, vibrations, or changes in performance, as these could indicate potential issues. Regular inspections allow for early detection and timely resolution of problems, preventing further damage and ensuring optimal performance of variators.

2. Lubrication:

Proper lubrication is crucial for the smooth operation and longevity of variators. Follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricants. Ensure that the variator is well lubricated, paying attention to the bearings, gears, and other moving parts. Insufficient lubrication can lead to increased friction, wear, and heat generation, compromising the performance and lifespan of variators. Regularly check the lubricant levels and top up or replace the lubricant as per the manufacturer’s specifications.

3. Cleaning and Debris Removal:

Keep variators clean and free from debris, dirt, and contaminants. Regularly inspect and clean the variator housing, cooling fins, and vents to ensure proper airflow and cooling. Remove any debris or foreign objects that may have entered the variator and could interfere with its operation. Accumulated debris can impede heat dissipation and interrupt the smooth movement of components, affecting the performance and reliability of variators.

4. Belt/Chain Inspection and Adjustment:

If the variator is part of a belt or chain-driven transmission system, it’s important to inspect and maintain the belts or chains. Check for signs of wear, damage, or improper tension. Replace worn or damaged belts or chains promptly, and ensure proper tension according to the manufacturer’s specifications. Incorrect belt/chain tension can lead to slippage, reduced power transmission efficiency, and premature wear on variators. Regular inspection and adjustment of belts or chains contribute to optimal performance and longevity of variators.

5. Temperature Monitoring:

Monitor the operating temperature of variators regularly. Excessive heat can be detrimental to variator performance and lifespan. Ensure that variators are operating within the recommended temperature range specified by the manufacturer. If the operating temperature exceeds the acceptable limits, investigate and address the underlying causes such as insufficient cooling, excessive friction, or overloading. Proper temperature management helps to prevent overheating, component degradation, and premature failure of variators.

6. Adherence to Manufacturer Guidelines:

Follow the maintenance guidelines provided by the variator manufacturer. Manufacturers often provide specific maintenance schedules, procedures, and recommendations for their variator models. Adhere to these guidelines regarding inspections, lubrication, cleaning, and any other maintenance requirements. Manufacturers’ guidelines are based on extensive testing and expertise, ensuring that the variators perform optimally and have a longer service life when proper maintenance practices are followed.

7. Professional Servicing:

For complex maintenance tasks or major repairs, it is advisable to seek professional servicing from authorized technicians or service centers. Trained professionals have the expertise, tools, and knowledge to perform intricate maintenance procedures and troubleshoot variator issues effectively. Professional servicing can help identify and address potential problems before they escalate, ensuring optimal performance and reliability of variators.

By following these maintenance practices, variators can maintain their optimal performance, efficiency, and lifespan. Regular inspections, proper lubrication, cleaning, belt/chain maintenance, temperature monitoring, adherence to manufacturer guidelines, and professional servicing all contribute to maximizing the performance and longevity of variators.

What is the impact of variators on the lifespan of mechanical components in a system?

The impact of variators on the lifespan of mechanical components in a system is a crucial consideration. Variators, such as continuously variable transmissions (CVTs), can have both positive and negative effects on the longevity of mechanical components. Here’s a detailed explanation of the impact of variators on the lifespan of mechanical components:

1. Reduced Wear and Tear:

Variators can contribute to reduced wear and tear on mechanical components compared to traditional transmissions with fixed gear steps. The continuously variable nature of variators allows for smoother and seamless gear ratio changes, eliminating the shock and stress associated with gear shifts in conventional transmissions. This smoother operation can reduce the strain on various components like gears, synchronizers, and clutch packs, potentially extending their lifespan.

2. Improved Power Delivery:

Variators optimize power delivery by continuously adjusting the gear ratios to keep the engine in its most efficient operating range. By operating the engine within its optimal powerband, variators can reduce the load and stress on mechanical components. When the engine operates more efficiently, it can lead to reduced wear on components like pistons, connecting rods, and crankshafts, potentially increasing their lifespan.

3. Enhanced Cooling and Lubrication:

Variators often incorporate advanced cooling and lubrication systems to maintain optimal operating conditions. These systems help manage heat generated during operation and ensure proper lubrication of critical components. Effective cooling and lubrication can prevent excessive heat buildup, reduce friction, and minimize wear on bearings, shafts, and other moving parts. By providing better cooling and lubrication, variators can help extend the lifespan of these mechanical components.

4. Increased Complexity and Component Interdependence:

Variators, especially electronic or computer-controlled ones, can introduce increased complexity and component interdependence within the system. The integration of electronic control systems, sensors, and actuators adds additional components that can potentially fail or require maintenance. The interdependence of these components means that a failure in one part can affect the overall performance and lifespan of the variator and other mechanical components. Proper maintenance, regular inspections, and timely repairs are crucial to mitigate potential issues and ensure the longevity of the system.

5. Maintenance and Service Requirements:

Variators may have specific maintenance and service requirements to ensure their optimal performance and longevity. Regular fluid changes, inspections, and adjustments may be necessary to keep the variator and associated mechanical components in good working condition. Adhering to the manufacturer’s recommended maintenance schedule is important to prevent premature wear and failure of components. Neglecting maintenance can lead to accelerated wear, reduced lifespan, and potential costly repairs.

6. Quality of Design and Manufacturing:

The overall lifespan of mechanical components in a variator system can be influenced by the quality of design and manufacturing. Variators and their associated components should be designed and manufactured to meet specific performance and durability standards. High-quality materials, precise engineering, and stringent quality control can contribute to the longevity of mechanical components. Variators from reputable manufacturers with a track record of reliability and performance are more likely to have a positive impact on the lifespan of mechanical components.

7. Driving Habits and Operating Conditions:

The impact of variators on the lifespan of mechanical components can also be influenced by driving habits and operating conditions. Aggressive driving, excessive loading, and operating the vehicle in extreme conditions can put additional stress on the variator and associated components. Continuous high RPM operation, abrupt throttle inputs, or towing heavy loads can accelerate wear and potentially shorten the lifespan of mechanical components. Operating the vehicle within recommended limits and practicing responsible driving habits can help preserve the longevity of the system.

In conclusion, variators can have both positive and negative impacts on the lifespan of mechanical components in a system. The continuously variable nature of variators can reduce wear and tear, improve power delivery, and enhance cooling and lubrication. However, increased complexity, maintenance requirements, and the quality of design and manufacturing are factors to consider. Additionally, driving habits and operating conditions play a significant role in determining the lifespan of mechanical components. Regular maintenance, proper care, and responsible driving practices are essential to ensure the longevity of the variator system and its associated mechanical components.

In what types of vehicles or machinery is a variator commonly used?

A variator is commonly used in various types of vehicles and machinery where the ability to provide variable speed or torque output is desirable. It offers advantages such as continuous gear ratio variation, stepless gear shifts, and optimized engine RPM. Here’s a detailed explanation of the types of vehicles and machinery where a variator is commonly used:

1. Automobiles:

One of the most common applications of a variator is in automobile transmissions. Continuously variable transmissions (CVTs) equipped with variators are increasingly being used in passenger cars, SUVs, and other vehicles. CVTs with variators provide smooth and seamless acceleration, improved fuel efficiency, and optimized power delivery. They are particularly beneficial in stop-and-go traffic situations and urban driving conditions.

2. Motorcycles and Scooters:

A variator is also commonly used in the transmissions of motorcycles and scooters. CVT systems with variators provide a smooth and responsive riding experience, allowing riders to easily adjust the speed and torque output. They offer advantages such as reduced gear shifting, improved acceleration, and enhanced fuel efficiency.

3. Industrial Machinery:

In industrial machinery applications, variators are used in systems that require adjustable speed or torque output. For example, variators can be found in conveyor systems, pumps, fans, and other equipment where precise control and flexibility are necessary. The ability to continuously vary the speed or torque allows for efficient operation and adaptability to different workloads.

4. Agricultural Equipment:

Agricultural machinery, such as tractors, combines, and harvesters, often use variators in their transmissions. The variators enable these machines to adjust their speed and torque output based on the specific requirements of different agricultural tasks. This flexibility allows for efficient operation in various field conditions and crop types.

5. Construction and Earthmoving Equipment:

In the construction and earthmoving industry, variators are used in machinery such as excavators, loaders, and bulldozers. These machines often require variable speed and torque to handle different tasks, such as digging, lifting, or pushing. Variators enable the equipment to adjust its output to match the specific requirements of each operation, improving productivity and control.

6. Marine Applications:

Variators are also utilized in marine applications, including boats, yachts, and ships. CVTs with variators provide smooth and efficient power delivery, allowing for precise control of the vessel’s speed. They offer benefits such as reduced vibration, improved fuel efficiency, and enhanced maneuverability.

In summary, variators are commonly used in automobiles, motorcycles, industrial machinery, agricultural equipment, construction and earthmoving machinery, and marine applications. They provide the ability to adjust speed or torque output continuously, resulting in improved performance, efficiency, and control in a wide range of vehicles and machinery.

editor by CX 2024-03-29