Product Description

Product Description

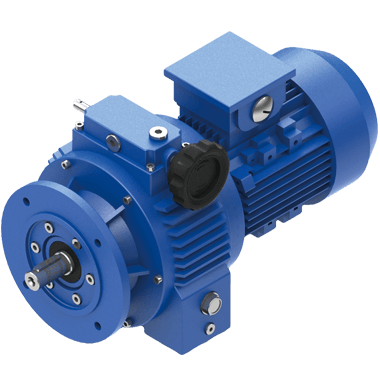

low backlash maintenance free 50W Small Reducer & speed variator for 5 axis machining center developed and manufactured by WEITENSTAN together with German and ZheJiang technicians for many years.

High precision miniature cycloidal gearbox has the characteristics of smaller, ultra-thin, lightweight and high rigidity, anti-overload and high torque. With good deceleration performance, smooth operation and accurate positioning can be achieved. Integrated design, can be directly connected with the motor, to achieve high precision, high rigidity, high durability and other advantages. It is designed for high speed ratio, high geometric accuracy, low motion loss, large torque capacity and high stiffness applications. The compact design (minimum OD ≈40mm, currently the world’s smallest precision cycloidal pin-wheel reducer) allows it to be installed in limited Spaces.

Reducer drawings

Detailed Photos

Product Advantage

low backlash maintenance free 50W Small Reducer & speed variator advantages:

1, fine precision cycloidal structure

Ultra flat shape is achieved through differential reduction mechanism and thin cross roller bearing, contributing to the compact size of the equipment. The combination of small size and unmatched superior parameters achieves the best combination of performance, price and size (high cost performance).

2. Excellent accuracy (transmission loss ≤1 arcmin)

Through the complex meshing of precision cycloid gear and high precision roller pin, higher transmission accuracy is achieved while maintaining small size and high speed ratio.

3, high rigidity

Increase the mesh rate to disperse the load, so the rigidity is high.

4. High overload capacity

It maintains trouble-free operation under abnormally low noise and vibration conditions while ensuring excellent overturning and torsional stiffness parameters. Integrated axial radial cross roller bearings, high load capacity and overload capacity of the reducer, can ensure users to provide a variety of temperature range of applications.

5, the motor installation is simple

Electromechanical integration design, can be directly connected with the motor, any brand of motor can be installed directly, without adding any device.

6. Maintenance free

Seal grease to achieve maintenance free. No refueling, no mounting direction restrictions.

7, stable performance

The manufacturing process of high wear-resistant materials and high precision parts has been certified by ISO9000 quality system, which guarantees the reliable operation of the reducer.

Product Classification

WF Series

High Precision Miniature Reducer

WF series is a high precision micro cycloidal reducer with flange, which has a wide range of applications. This series of reducers includes precise reduction mechanisms and radial – axial roller bearings. The unique design allows load to act directly on the output flange or housing without additional bearings. WF series reducer is characterized by module design, can be installed through the flange motor and reducer, belongs to the motor directly connected reducer.

WFH Series

High Precision Miniature Reducer

WFH series is a hollow form of high precision miniature cycloidal reducer, wire, compressed air pipeline, drive shaft can be through the hollow shaft, non-motor direct connection type reducer. The WFH series is fully sealed, full of grease and includes precise deceleration mechanism and radial – axial roller bearings. The unique design allows load to be acted directly on the output flange or housing without additional bearings.

Product Parameters

| Size | reduction ratio | Rated output moment | Allowable torque of start and stop | Instantaneous allowable moment | Rated input speed | Maximum input speed | Tilt stiffness | Torsional stiffness | No-load starting torque | Transmission accuracy | Error accuracy | Moment of inertia | Weight | |

| Axis rotation | Shell rotation | Nm | Nm | Nm | rpm | rpm | Nm/arcmin | Nm/arcmin | Nm | arcmin | arcmin | kg-m² | kg | |

| WF07 | 21 | 20 | 15 | 30 | 45 | 3000 | 6000 | 6 | 1.1 | 0.12 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 0.52 | 0.42 |

| 41 | 40 | 0.11 | 0.47 | |||||||||||

| WF17 | 21 | 20 | 50 | 100 | 150 | 3000 | 6000 | 28 | 6 | 0.21 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 0.88 | 0.85 |

| 41 | 40 | 0.18 | 0.72 | |||||||||||

| 61 | 60 | 0.14 | 0.69 | |||||||||||

| WF25 | 21 | 20 | 110 | 220 | 330 | 3000 | 5500 | 131 | 24 | 0.47 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 6.12 | 2 |

| 31 | 30 | 0.41 | 5.67 | |||||||||||

| 41 | 40 | 0.38 | 4.9 | |||||||||||

| 51 | 50 | 0.35 | 4.56 | |||||||||||

| 81 | 80 | 0.31 | 4.25 | |||||||||||

| WF32 | 25 | 24 | 190 | 380 | 570 | 3000 | 4500 | 240 | 35 | 1.15 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 11 | 4.2 |

| 31 | 30 | 1.1 | 10.8 | |||||||||||

| 51 | 50 | 0.77 | 9.35 | |||||||||||

| 81 | 80 | 0.74 | 8.32 | |||||||||||

| 101 | 100 | 0.6 | 7.7 | |||||||||||

| WF40 | 25 | 24 | 320 | 640 | 960 | 3000 | 4000 | 377 | 50 | 1.35 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 13.2 | 6.6 |

| 31 | 30 | 1.32 | 12.96 | |||||||||||

| 51 | 50 | 0.92 | 11.22 | |||||||||||

| 81 | 80 | 0.81 | 9.84 | |||||||||||

| 121 | 120 | 0.72 | 8.4 | |||||||||||

Installation Instructions

Company Profile

Q: Speed reducer grease replacement time

A: When sealing appropriate amount of grease and running reducer, the standard replacement time is 20000 hours according to the aging condition of the grease. In addition, when the grease is stained or used in the surrounding temperature condition (above 40ºC), please check the aging and fouling of the grease, and specify the replacement time.

Q: Delivery time

A: Fubao has 2000+ production base, daily output of 1000+ units, standard models within 7 days of delivery.

Q: Reducer selection

A: Fubao provides professional product selection guidance, with higher product matching degree, higher cost performance and higher utilization rate.

Q: Application range of reducer

A: Fubao has a professional research and development team, complete category design, can match any stepping motor, servo motor, more accurate matching.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Humanoid Robot |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the design of variators contribute to energy savings and reduced emissions?

Variators are designed with several key features and mechanisms that contribute to energy savings and reduced emissions. These design aspects focus on optimizing power transmission efficiency, reducing mechanical losses, and enabling better control over the powertrain. Here’s a detailed explanation of how the design of variators contributes to energy savings and reduced emissions:

1. Continuously Variable Transmission (CVT) Design:

Variators, particularly those used in CVTs, offer a continuously variable gear ratio, allowing the engine to operate at its most efficient speed for a given driving condition. Unlike traditional transmissions with fixed gear ratios, CVTs enable the engine to stay within its optimal power band, resulting in improved fuel efficiency. The continuously variable nature of CVTs ensures that the engine can maintain an optimal RPM (revolutions per minute) regardless of the vehicle speed, reducing unnecessary fuel consumption and emissions.

2. Friction Reduction:

Variators are designed to minimize friction and mechanical losses in the power transmission system. Friction reduction measures, such as the use of low-friction materials, improved lubrication systems, and optimized bearing designs, help to minimize energy losses during power transmission. By reducing friction, variators improve the overall efficiency of the powertrain, allowing more energy from the engine to be effectively transferred to the wheels or driven machinery, resulting in energy savings and reduced emissions.

3. Lightweight Construction:

The design of variators focuses on lightweight construction using materials that offer high strength and durability. By reducing the weight of variators, the overall weight of the vehicle or machinery can be reduced. A lighter vehicle or machinery requires less energy to accelerate, decelerate, and operate, resulting in improved energy efficiency. Additionally, lighter components in variators also contribute to reduced mechanical losses and improved overall system efficiency.

4. Efficient Power Flow:

Variators are designed to ensure efficient power flow from the engine to the wheels or driven machinery. They are engineered to minimize power losses during transmission, ensuring that a maximum amount of power is delivered to the wheels or machinery. By optimizing power flow, variators help to reduce energy waste and improve overall energy efficiency, resulting in energy savings and reduced emissions.

5. Advanced Control Systems:

Modern variators often incorporate advanced control systems that optimize power delivery and engine operation. These control systems continuously monitor various parameters, such as throttle input, vehicle speed, and engine load, and adjust the gear ratio accordingly. By precisely controlling the powertrain, variators help to minimize unnecessary fuel consumption and emissions. Additionally, advanced control systems can also facilitate regenerative braking and energy recovery, further enhancing energy savings and reducing emissions.

6. Integration with Hybrid and Electric Powertrains:

Variators are designed to integrate seamlessly with hybrid and electric powertrains. In hybrid vehicles, variators play a crucial role in efficiently transferring power between the internal combustion engine and the electric motor. They enable smooth transitions between different power sources, optimizing energy usage and reducing emissions. In electric vehicles, variators are often used in conjunction with single-speed transmissions to provide efficient power delivery from the electric motor to the wheels, contributing to energy savings and reduced emissions.

7. Compliance with Emission Regulations:

The design of variators takes into account emission regulations and standards imposed by regulatory bodies. Manufacturers ensure that variators meet or exceed these regulations by incorporating features that minimize emissions and improve fuel efficiency. This includes optimizing gear ratios for reduced fuel consumption, implementing efficient control systems, and utilizing technologies such as regenerative braking and energy recovery. By complying with emission regulations, variators contribute to reduced emissions and environmental impact.

In conclusion, the design of variators incorporates features that optimize power transmission efficiency, reduce mechanical losses, and enable better control over the powertrain. These design aspects, such as continuously variable transmission design, friction reduction, lightweight construction, efficient power flow, advanced control systems, integration with hybrid/electric powertrains, and compliance with emission regulations, contribute to energy savings and reduced emissions. By improving overall system efficiency and optimizing power delivery, variators play a significant role in achieving energy efficiency and environmental sustainability in vehicles and machinery.

What is the impact of variators on the lifespan of mechanical components in a system?

The impact of variators on the lifespan of mechanical components in a system is a crucial consideration. Variators, such as continuously variable transmissions (CVTs), can have both positive and negative effects on the longevity of mechanical components. Here’s a detailed explanation of the impact of variators on the lifespan of mechanical components:

1. Reduced Wear and Tear:

Variators can contribute to reduced wear and tear on mechanical components compared to traditional transmissions with fixed gear steps. The continuously variable nature of variators allows for smoother and seamless gear ratio changes, eliminating the shock and stress associated with gear shifts in conventional transmissions. This smoother operation can reduce the strain on various components like gears, synchronizers, and clutch packs, potentially extending their lifespan.

2. Improved Power Delivery:

Variators optimize power delivery by continuously adjusting the gear ratios to keep the engine in its most efficient operating range. By operating the engine within its optimal powerband, variators can reduce the load and stress on mechanical components. When the engine operates more efficiently, it can lead to reduced wear on components like pistons, connecting rods, and crankshafts, potentially increasing their lifespan.

3. Enhanced Cooling and Lubrication:

Variators often incorporate advanced cooling and lubrication systems to maintain optimal operating conditions. These systems help manage heat generated during operation and ensure proper lubrication of critical components. Effective cooling and lubrication can prevent excessive heat buildup, reduce friction, and minimize wear on bearings, shafts, and other moving parts. By providing better cooling and lubrication, variators can help extend the lifespan of these mechanical components.

4. Increased Complexity and Component Interdependence:

Variators, especially electronic or computer-controlled ones, can introduce increased complexity and component interdependence within the system. The integration of electronic control systems, sensors, and actuators adds additional components that can potentially fail or require maintenance. The interdependence of these components means that a failure in one part can affect the overall performance and lifespan of the variator and other mechanical components. Proper maintenance, regular inspections, and timely repairs are crucial to mitigate potential issues and ensure the longevity of the system.

5. Maintenance and Service Requirements:

Variators may have specific maintenance and service requirements to ensure their optimal performance and longevity. Regular fluid changes, inspections, and adjustments may be necessary to keep the variator and associated mechanical components in good working condition. Adhering to the manufacturer’s recommended maintenance schedule is important to prevent premature wear and failure of components. Neglecting maintenance can lead to accelerated wear, reduced lifespan, and potential costly repairs.

6. Quality of Design and Manufacturing:

The overall lifespan of mechanical components in a variator system can be influenced by the quality of design and manufacturing. Variators and their associated components should be designed and manufactured to meet specific performance and durability standards. High-quality materials, precise engineering, and stringent quality control can contribute to the longevity of mechanical components. Variators from reputable manufacturers with a track record of reliability and performance are more likely to have a positive impact on the lifespan of mechanical components.

7. Driving Habits and Operating Conditions:

The impact of variators on the lifespan of mechanical components can also be influenced by driving habits and operating conditions. Aggressive driving, excessive loading, and operating the vehicle in extreme conditions can put additional stress on the variator and associated components. Continuous high RPM operation, abrupt throttle inputs, or towing heavy loads can accelerate wear and potentially shorten the lifespan of mechanical components. Operating the vehicle within recommended limits and practicing responsible driving habits can help preserve the longevity of the system.

In conclusion, variators can have both positive and negative impacts on the lifespan of mechanical components in a system. The continuously variable nature of variators can reduce wear and tear, improve power delivery, and enhance cooling and lubrication. However, increased complexity, maintenance requirements, and the quality of design and manufacturing are factors to consider. Additionally, driving habits and operating conditions play a significant role in determining the lifespan of mechanical components. Regular maintenance, proper care, and responsible driving practices are essential to ensure the longevity of the variator system and its associated mechanical components.

Can you provide examples of products or machinery that use variators for speed control?

Yes, variators are used in a wide range of products and machinery for speed control purposes. The ability to adjust the gear ratio continuously makes variators ideal for applications where precise speed control is required. Here are some examples of products and machinery that utilize variators for speed control:

1. Automobiles:

In the automotive industry, variators are commonly used in continuously variable transmissions (CVTs) for speed control in passenger cars, SUVs, and other vehicles. CVTs with variators allow for seamless and continuous adjustment of the gear ratio, enabling precise speed control and efficient power delivery. Variators in automobiles contribute to improved fuel efficiency, smoother acceleration, and enhanced driving comfort.

2. Motorcycles and Scooters:

Variators are also utilized in the transmissions of motorcycles and scooters for speed control. CVTs with variators provide riders with the ability to adjust the speed output smoothly and precisely. By continuously varying the gear ratio, variators offer a responsive and customizable riding experience, allowing riders to adapt to different road conditions and riding preferences.

3. Industrial Machinery:

In industrial settings, variators are used in various types of machinery that require speed control. For example, variators can be found in conveyor systems, where they allow for precise adjustment of the conveyor belt speed to match the specific production requirements. Variators are also used in pumps, fans, mixers, and other equipment that need variable speed control to optimize performance and energy consumption.

4. Agricultural Equipment:

Agricultural machinery, such as tractors, combines, and harvesters, often utilize variators for speed control. Variators in these machines allow farmers and operators to adjust the speed according to the specific tasks at hand, such as plowing, seeding, or harvesting. This flexibility enables efficient operation in various agricultural operations and field conditions.

5. Construction and Earthmoving Equipment:

Variators are used in construction and earthmoving equipment to regulate the speed of machines like excavators, loaders, and bulldozers. By controlling the gear ratio, variators enable operators to adjust the speed of these machines, allowing for precise and efficient performance in tasks such as digging, lifting, and pushing materials.

6. Marine Applications:

Marine vessels, including boats, yachts, and ships, utilize variators for speed control. In marine applications, variators are employed to adjust the propeller speed and optimize power delivery based on the desired speed and operating conditions. Variators in marine applications offer benefits such as improved fuel efficiency, enhanced maneuverability, and smooth acceleration.

7. HVAC Systems:

Variators are used in heating, ventilation, and air conditioning (HVAC) systems for speed control of fans and blowers. By adjusting the gear ratio, variators allow for precise control of the airflow, ensuring that the fans operate at the desired speed for efficient heating, cooling, and ventilation in residential, commercial, and industrial settings.

8. Exercise Equipment:

In the fitness industry, variators are employed in exercise equipment such as treadmills, elliptical trainers, and stationary bikes. Variators enable users to adjust the speed and resistance levels of the equipment, providing a customizable workout experience to meet individual fitness goals and preferences.

In summary, variators for speed control are utilized in a wide range of products and machinery, including automobiles, motorcycles, industrial machinery, agricultural equipment, construction and earthmoving machinery, marine applications, HVAC systems, and exercise equipment. The ability to continuously adjust the gear ratio allows for precise speed control, optimizing performance and efficiency in various applications.

editor by CX 2024-03-23