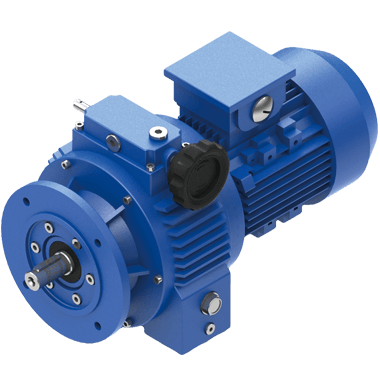

Product Description

Product Description

Product Characteristics:

1.High speed-regulating precision :0.5-1 rotation

2.High speed-changing range: ratio from 1:1.4 to 1:7 freely;

3.High strength and long service life

4.Convenient to regulate speed

5.Can run continuously, front to back running direction, smooth running,stable performance, and low noise.

6.Sealed fully and suitable for any environment

7.Companct structure and small volume

8.Made of high quality aluminium alloy diecast into foarming, nice appearance,light weight and non-rusty.9.Good adaptation:UDL series speed variators can be combined with all kinds of speed reducers to achive low stepless speed regulating(such as R-K-F-S Series and NMRV worm reducers).

Applications:

UDL series stepless speed variators are widely used for foodstaffs, packing, chemicals,pharmacy,plastics, paper-making, machine tools,communications and all kinds of automatic lines,pipelines and assembly lines which need speed regulating. It is a good companion for production machines.

Detailed Photos

Product Parameters

| PERFORMANCE PARAMETER | ||||

| Performance table for UDL series speed variators(n1=1400r/min) | ||||

| Motor Power | Model | i | n2(r/min) | M2(Nm) |

| 0.18KW | UDL002(UDL0.18) | 1.6∽8.2 | 880∽170 | 1.5∽3 |

| 0.37KW | UDL005(UDL0.37) | 1.4∽7 | 1000∽200 | 3∽6 |

| 0.75KW | UDL571(UDL0.75) | 1.4∽7 | 1000∽200 | 6∽12 |

| 1.5KW | UD571(UD1.5) | 1.4∽7 | 1000∽200 | 12∽24 |

| 2.2KW | UD030(UD2.2) | 1.4∽7 | 1000∽200 | 18∽36 |

| 3.0KW | UD040(UD3.0) | 1.4∽7 | 1000∽200 | 24∽48 |

| 4.0KW | UD050(UD4.0) | 1.4∽7 | 1000∽200 | 32∽64 |

Outline Dimension:

Company Profile

About our company:

We are a professional reducer manufacturer located in HangZhou, ZHangZhoug province.Our leading products is full range of RV571-150 worm reducers , also supplied hypoid helical gearbox, PC units, UDL Variators and AC Motors.Products are widely used for applications such as: foodstuffs, ceramics, packing, chemicals, pharmacy, plastics, paper-making, construction machinery, metallurgic mine, environmental protection engineering, and all kinds of automatic lines, and assembly lines.With fast delivery, superior after-sales service, advanced producing facility, our products sell well both at home and abroad. We have exported our reducers to Southeast Asia, Eastern Europe and the Middle East and so on.Our aim is to develop and innovate on the basis of high quality, and create a good reputation for reducers.

Workshop:

Exhibition:

We participate Germany Hannver Exhibition-ZheJiang PTC Fair-Turkey Win Eurasia

Packaging & Shipping

Packing information:Plastic Bags+Cartons+Wooden Cases , or on request.

Installation Instructions

To install the reducer, it is necessary to note the following issues:

1)Check the correct rotation direction of output shaft before fitting reducer to machines.

2)Before mounting, pls check shaft diameter, bore diameter, key and keyway, to be sure their dimension are not deviation; In order to keep good performance, also pls avoid assembling too tight or too loose.

3)Reducer must be mounted to machines stably to avoid vibration.

4)Whenever possible,protect the reducer against solar radiation and bad weather.

5)In the case of particularly lengthy period of storage(4-6 months), if the oil seal is not immersed in lubricant inside the unit, it is recommended to change it since the rubber could stick to the shaft or may even have lost the elasticity.

6)Painting must definitely not go over rubber parts and the holes on breather plug if any.

7)When connect with hollow or CHINAMFG shaft, pls grease the joint to avoid lock or oxidation.

8)Check the correct lubricant level through indicator if there is one.

9)Starting must take place gradually, without immediately applying the maximum load.

10)When using various of motors to match reducer directly, supporting unit is required if motor is too heavy.

11)Ensure good heat dissipation by keeping good ventilation near the motor fan.

12)In the case of ambient temperature40ºC, pls call the technical department.

After Sales Service

1.Maintenance Time and Warranty:Within 1 year after receiving goods.

2.Other Service: Including modeling selection guide, installation guide, and problem resolution guide, etc.

FAQ

1.Q:Can you make as per customer drawing?

A: Yes, we offer customized service for customers accordingly. We can use customer’s nameplate for gearboxes.

2.Q:What is your terms of payment ?

A: 30% deposit before production,balance T/T before delivery.

3.Q:Are you a trading company or manufacturer?

A:We are a manufacurer with advanced equipment and experienced workers.

4.Q:What’s your production capacity?

A:8000-9000 PCS/MONTH

5.Q:Free sample is available or not?

A:Yes, we can supply free sample if customer agree to pay for the courier cost

6.Q:Do you have any certificate?

A:Yes, we have CE certificate and SGS certificate report.

Contact information:

Ms Lingel Pan

For any questions just feel free ton contact me. Many thanks for your kind attention to our company!

| Application: | Motor, Machinery, Marine, Agricultural Machinery, Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical or Horizontal Type |

| Step: | Stepless |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What maintenance practices are recommended for variators to ensure optimal performance?

To ensure optimal performance and longevity of variators, certain maintenance practices are recommended. These practices focus on regular inspections, proper lubrication, and adherence to manufacturer guidelines. Here’s a detailed explanation of the maintenance practices recommended for variators:

1. Regular Inspections:

Regular inspections are essential to identify any signs of wear, damage, or abnormal operation in variators. Inspect variators visually for leaks, loose fasteners, or any visible damage. Pay attention to abnormal noises, vibrations, or changes in performance, as these could indicate potential issues. Regular inspections allow for early detection and timely resolution of problems, preventing further damage and ensuring optimal performance of variators.

2. Lubrication:

Proper lubrication is crucial for the smooth operation and longevity of variators. Follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricants. Ensure that the variator is well lubricated, paying attention to the bearings, gears, and other moving parts. Insufficient lubrication can lead to increased friction, wear, and heat generation, compromising the performance and lifespan of variators. Regularly check the lubricant levels and top up or replace the lubricant as per the manufacturer’s specifications.

3. Cleaning and Debris Removal:

Keep variators clean and free from debris, dirt, and contaminants. Regularly inspect and clean the variator housing, cooling fins, and vents to ensure proper airflow and cooling. Remove any debris or foreign objects that may have entered the variator and could interfere with its operation. Accumulated debris can impede heat dissipation and interrupt the smooth movement of components, affecting the performance and reliability of variators.

4. Belt/Chain Inspection and Adjustment:

If the variator is part of a belt or chain-driven transmission system, it’s important to inspect and maintain the belts or chains. Check for signs of wear, damage, or improper tension. Replace worn or damaged belts or chains promptly, and ensure proper tension according to the manufacturer’s specifications. Incorrect belt/chain tension can lead to slippage, reduced power transmission efficiency, and premature wear on variators. Regular inspection and adjustment of belts or chains contribute to optimal performance and longevity of variators.

5. Temperature Monitoring:

Monitor the operating temperature of variators regularly. Excessive heat can be detrimental to variator performance and lifespan. Ensure that variators are operating within the recommended temperature range specified by the manufacturer. If the operating temperature exceeds the acceptable limits, investigate and address the underlying causes such as insufficient cooling, excessive friction, or overloading. Proper temperature management helps to prevent overheating, component degradation, and premature failure of variators.

6. Adherence to Manufacturer Guidelines:

Follow the maintenance guidelines provided by the variator manufacturer. Manufacturers often provide specific maintenance schedules, procedures, and recommendations for their variator models. Adhere to these guidelines regarding inspections, lubrication, cleaning, and any other maintenance requirements. Manufacturers’ guidelines are based on extensive testing and expertise, ensuring that the variators perform optimally and have a longer service life when proper maintenance practices are followed.

7. Professional Servicing:

For complex maintenance tasks or major repairs, it is advisable to seek professional servicing from authorized technicians or service centers. Trained professionals have the expertise, tools, and knowledge to perform intricate maintenance procedures and troubleshoot variator issues effectively. Professional servicing can help identify and address potential problems before they escalate, ensuring optimal performance and reliability of variators.

By following these maintenance practices, variators can maintain their optimal performance, efficiency, and lifespan. Regular inspections, proper lubrication, cleaning, belt/chain maintenance, temperature monitoring, adherence to manufacturer guidelines, and professional servicing all contribute to maximizing the performance and longevity of variators.

What is the impact of variators on the lifespan of mechanical components in a system?

The impact of variators on the lifespan of mechanical components in a system is a crucial consideration. Variators, such as continuously variable transmissions (CVTs), can have both positive and negative effects on the longevity of mechanical components. Here’s a detailed explanation of the impact of variators on the lifespan of mechanical components:

1. Reduced Wear and Tear:

Variators can contribute to reduced wear and tear on mechanical components compared to traditional transmissions with fixed gear steps. The continuously variable nature of variators allows for smoother and seamless gear ratio changes, eliminating the shock and stress associated with gear shifts in conventional transmissions. This smoother operation can reduce the strain on various components like gears, synchronizers, and clutch packs, potentially extending their lifespan.

2. Improved Power Delivery:

Variators optimize power delivery by continuously adjusting the gear ratios to keep the engine in its most efficient operating range. By operating the engine within its optimal powerband, variators can reduce the load and stress on mechanical components. When the engine operates more efficiently, it can lead to reduced wear on components like pistons, connecting rods, and crankshafts, potentially increasing their lifespan.

3. Enhanced Cooling and Lubrication:

Variators often incorporate advanced cooling and lubrication systems to maintain optimal operating conditions. These systems help manage heat generated during operation and ensure proper lubrication of critical components. Effective cooling and lubrication can prevent excessive heat buildup, reduce friction, and minimize wear on bearings, shafts, and other moving parts. By providing better cooling and lubrication, variators can help extend the lifespan of these mechanical components.

4. Increased Complexity and Component Interdependence:

Variators, especially electronic or computer-controlled ones, can introduce increased complexity and component interdependence within the system. The integration of electronic control systems, sensors, and actuators adds additional components that can potentially fail or require maintenance. The interdependence of these components means that a failure in one part can affect the overall performance and lifespan of the variator and other mechanical components. Proper maintenance, regular inspections, and timely repairs are crucial to mitigate potential issues and ensure the longevity of the system.

5. Maintenance and Service Requirements:

Variators may have specific maintenance and service requirements to ensure their optimal performance and longevity. Regular fluid changes, inspections, and adjustments may be necessary to keep the variator and associated mechanical components in good working condition. Adhering to the manufacturer’s recommended maintenance schedule is important to prevent premature wear and failure of components. Neglecting maintenance can lead to accelerated wear, reduced lifespan, and potential costly repairs.

6. Quality of Design and Manufacturing:

The overall lifespan of mechanical components in a variator system can be influenced by the quality of design and manufacturing. Variators and their associated components should be designed and manufactured to meet specific performance and durability standards. High-quality materials, precise engineering, and stringent quality control can contribute to the longevity of mechanical components. Variators from reputable manufacturers with a track record of reliability and performance are more likely to have a positive impact on the lifespan of mechanical components.

7. Driving Habits and Operating Conditions:

The impact of variators on the lifespan of mechanical components can also be influenced by driving habits and operating conditions. Aggressive driving, excessive loading, and operating the vehicle in extreme conditions can put additional stress on the variator and associated components. Continuous high RPM operation, abrupt throttle inputs, or towing heavy loads can accelerate wear and potentially shorten the lifespan of mechanical components. Operating the vehicle within recommended limits and practicing responsible driving habits can help preserve the longevity of the system.

In conclusion, variators can have both positive and negative impacts on the lifespan of mechanical components in a system. The continuously variable nature of variators can reduce wear and tear, improve power delivery, and enhance cooling and lubrication. However, increased complexity, maintenance requirements, and the quality of design and manufacturing are factors to consider. Additionally, driving habits and operating conditions play a significant role in determining the lifespan of mechanical components. Regular maintenance, proper care, and responsible driving practices are essential to ensure the longevity of the variator system and its associated mechanical components.

Can you describe the benefits of using a variator in terms of efficiency and performance?

Using a variator in various applications can offer significant benefits in terms of efficiency and performance. The ability to continuously adjust the gear ratio and optimize engine RPM contributes to improved fuel economy, smoother power delivery, and enhanced overall performance. Here’s a detailed explanation of the benefits of using a variator:

1. Improved Fuel Efficiency:

A variator allows for precise control of the gear ratio, enabling the engine to operate within its optimal RPM range. By continuously adjusting the gear ratio to match the driving conditions, the engine can maintain an efficient power output. This optimized engine RPM helps to reduce fuel consumption and improve overall fuel efficiency. Variators are particularly beneficial in situations that involve frequent speed changes or stop-and-go traffic, where traditional gear systems may be less efficient.

2. Smoother Power Delivery:

Traditional gear systems have discrete gear ratios, resulting in noticeable gear shifts when changing gears. In contrast, a variator provides stepless gear shifts, allowing for a smooth and seamless power delivery. The continuous adjustment of the gear ratio ensures that the engine operates at the most suitable RPM for the current driving conditions, resulting in a smoother acceleration and a more refined driving experience.

3. Optimal Performance:

A variator enables the engine to operate within its optimal power band. By continuously varying the gear ratio, the variator keeps the engine RPM at an ideal level, maximizing power output and torque delivery. This translates into improved performance, whether it’s for quick acceleration, high-speed cruising, or towing heavy loads. The ability to maintain optimal performance across a wide range of driving conditions is a significant advantage of using a variator.

4. Adaptability to Driving Conditions:

A variator allows for seamless adaptation to different driving conditions. It can adjust the gear ratio based on factors such as vehicle speed, throttle input, and load requirements. This adaptability ensures that the engine operates efficiently and delivers the appropriate power for specific driving situations. Whether it’s accelerating from a standstill, maintaining a constant speed, or climbing steep inclines, the variator can optimize the gear ratio to suit the demands of the moment.

5. Reduced Wear and Tear:

Due to the smooth and continuous power delivery, variators help to reduce wear and tear on various components of the drivetrain. The absence of abrupt gear shifts and the ability to maintain optimal engine RPM contribute to reduced stress on the engine, transmission, and other driveline components. This can result in increased longevity and reliability of the vehicle or machinery.

6. Enhanced Driving Comfort:

The smooth and seamless power delivery provided by a variator contributes to enhanced driving comfort. The absence of gear shifts and the ability to maintain the engine RPM in the optimal range reduce vibrations, noise, and harshness. This leads to a more refined and enjoyable driving experience, particularly in urban driving conditions or during long-distance journeys.

In summary, using a variator in various applications offers benefits in terms of improved fuel efficiency, smoother power delivery, optimal performance, adaptability to driving conditions, reduced wear and tear, and enhanced driving comfort. These advantages make variators a desirable choice for achieving greater efficiency and performance in vehicles and machinery.

editor by CX 2023-12-08