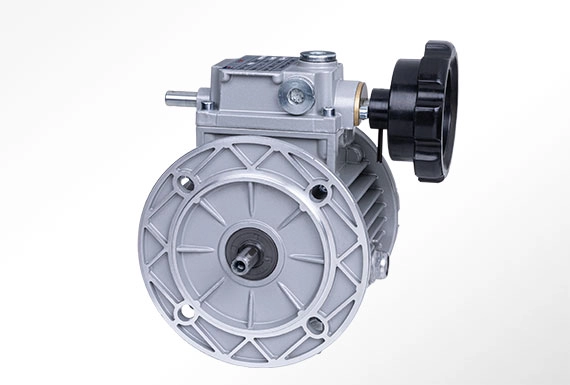

Product Description

0.75KW/1HP frequency variator for Meat cutter Mixer CE

APPLICATION —– WATER PUMP

CHZIRI Product Acessories

TECHNICAL OF ZVF300H SERIES

1. Output frequency: 0-600Hz.

2. Multiple password protection mode

3. Remote control operation keypad,convenient for remote control.

4. V/F curve &multi-inflection point setting,flexible configuration.

5. Keyboard parameter copy function.Easy to set the parameters for multi-inverters.

6. Wide industry application.To expand special function according to different industries.

7. Multiple hardware and software protection and optimized hardware for anti-interference technology.

8. Multi-step speed and wobble frequency running (external terminal 15 steps speed control).

9. Unique adaptive control technology.Auto current limiting and voltage limiting and under-voltage restrain.

10. Optimized external installation and internal structure and independent air flue design,fully enclosed electrical space design.

11. Output automatic voltage regulation function.(AVR),automatically adjust the output pulse width.To eliminate the influence of the grid change on load.

12. Built-in PID regulation function to facilitate the realization of closed loop control of the temperature, pressure and flow.And reduce the cost of the control system.

13. Standard MODBUS communication protocol.Easy to achieve the communication between PLC, IPC and other industrial equipments.

APPLICATION

Outline Dimension (unit:mm)

| Inverter Model | Power (KW) G/P |

Current (A) |

Dimension (mm) | Figure | |||||

| H | H1 | W | W1 | D | d | ||||

| ZVF300H-G0RT4S | 0.75KW | 2.5A | 215 | 205 | 145 | 135 | 193 | Φ4 | Fig.1 |

Scope of application:

CHINAMFG frequency inverter applied at the metallurgy, plastomer,textile,food-stuff,petroleum,chemical industry,paper-making,pharmacy,printing, building material,crane,music spring,water supply systerm and all kinds of machine equipment.As AC asynchronous motor’s driving and speed control.

Frequency Inverter can use in the following environmental

| Ambient | Place to be used | Indoor location free from direct exposure to sun light, high humidity or dew condensation, high levels of dust, corrosive gas, explosive gas, inflammable gas, oil mist, salt and etc |

| Altitude | Below 1000 M | |

| Ambient Temperature | -10 C to +45 C (Bare Machine: -10 C to+50 C) | |

| Humidity | 20%-90% RH without dew condensation | |

| Vibration | <0.5G | |

| Storage temperature | -20~+60C | |

| Structure | Protection class | IP20 |

| Cooling mode | Forced air cooling | |

| Installation mode | Wall mounted or floor-type actuator |

PACKAGE

ISO AND CE CERTIFICATE

FROM OUR CUSTOMER

Customer Support

- Email Customer Support:

24 hours working time .

All emails will be responded to within 2 hours.

Returns

Please note that all returns must be pre-approved by us.Unauthorized returns will not be accepted.If you need to return,please check twice to confirm the item not work and contact our customer service representative,let us know the detailed problem and send us some pictures for confirmation.

We ONLY accept returns with original package.Please make sure that item has NO man-made sabotage.Used items will not be accepted for return.

FAQ

1. Can I get some samples?

Yes.Sample order is available for quality check and market test .But you have to pay for it .

2. What’s delivery time?

It usually takes about 3-5 working days for small order and 10-15 days for big order.

3. What’s your payment terms?

We usually accept all kinds of payment terms.Such as T/T,L/C.Western Union.Cash.

4. What’s your warranty terms?

We offer 12 months warranty time .

5. Do you have the products in stock?

Depends on your request ,We have standard models in stock.Some special products and big order will be newly produced according to your order.

6. Can I mix different power in 1 container.

Yes,Different models can be mixed up in 1 container,even 1 order.

7. How does your factory do the quality control?

Quality is priority,we always attach the importance to quality control from the beginning to the end of the production,every product will be fully assembled and carefully tested before packing and shipping.

8. Can you sell spare parts ?

If you are using CHINAMFG products,we can sell spare parts to you.But we couldn’t sell the half-finished products.

9.I would like to know if you have a partner for export?

Yes .CHZIRI Electrical have the right to export and can sell electrical product all over the world..

10. Can you make the inverter and soft starter control boards (switchgear)?

Yes. We have a lot of experience to design frequency inverter and soft starter cabinet according to your request.But you can send us the wiring diagram.

11.Can the inverter connect with computer?

Yes .All inverters have built-in RS485 port,and support Modbus communication protocol.

12.How can I trust you ?

The core of CHINAMFG electrical culture is honesty and loyalty,our company has been audited and approved ISO9001,CE.CCC.Assessment report will could be sent to you by e-mail,also,we are the made-in-china’s gold supplier since 2008.Now we have clients all around the world. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | to Drive and Control The Speed of The Motor |

|---|---|

| Output Type: | Triple |

| Principle of Work: | SVC Control , V/F Control. Torque Control |

| Samples: |

US$ 92/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do variators contribute to smoother acceleration and deceleration in vehicles?

Variators play a significant role in achieving smoother acceleration and deceleration in vehicles, particularly those equipped with continuously variable transmissions (CVTs). The continuous and seamless adjustment of the gear ratio provided by variators allows for precise control of engine speed and power delivery, resulting in smoother changes in vehicle speed. Here’s how variators contribute to smoother acceleration and deceleration:

1. Continuous Gear Ratio Adjustment:

Variators in CVTs enable the continuous adjustment of the gear ratio, allowing the engine to operate at the most efficient and effective speed for a given driving condition. Unlike traditional transmissions with fixed gear ratios, variators provide an infinite number of gear ratios within their operating range. This continuous adjustment ensures that the vehicle’s engine stays within its optimal power band, resulting in smooth and responsive acceleration and deceleration.

2. Elimination of Gear Shifts:

Traditional transmissions with discrete gear ratios require frequent gear shifts during acceleration and deceleration, which can cause jerky movements or interruptions in power delivery. In contrast, variators eliminate the need for gear shifts altogether. The smooth and continuous adjustment of the gear ratio by the variator allows the engine to maintain a consistent and optimal speed, resulting in seamless acceleration and deceleration without the interruption of gear changes.

3. Precise Engine Control:

Variators enable precise control of the engine speed, allowing for finer adjustments during acceleration and deceleration. The engine speed can be matched more closely to the desired vehicle speed, resulting in smoother transitions. By continuously optimizing the gear ratio based on the driver’s input and the vehicle’s operating conditions, variators ensure that the engine operates in its most efficient range, leading to smoother acceleration and deceleration.

4. Adaptive Power Delivery:

Variators in modern CVTs are often equipped with advanced control systems that adapt the power delivery to match the driver’s demands and the road conditions. These control systems monitor various parameters such as throttle input, vehicle speed, and engine load, and adjust the gear ratio accordingly to provide the desired acceleration or deceleration response. This adaptive power delivery ensures that the vehicle responds smoothly to the driver’s inputs, enhancing the overall driving experience.

5. Seamless Transitions:

The continuous and infinite gear ratios provided by variators allow for seamless transitions between different driving conditions. Whether it’s transitioning from a standing start to cruising speed or decelerating from high speed to a stop, variators ensure that the changes in vehicle speed are gradual and smooth. This eliminates the abrupt shifts that can occur with traditional transmissions, resulting in a more comfortable and refined driving experience.

In summary, variators, particularly in vehicles equipped with CVTs, contribute to smoother acceleration and deceleration by providing continuous gear ratio adjustment, eliminating gear shifts, enabling precise engine control, facilitating adaptive power delivery, and ensuring seamless transitions between different driving conditions. These features result in improved drivability, reduced jerkiness, and enhanced comfort for the driver and passengers.

Are there aftermarket upgrades available for variators to enhance their functionality?

Yes, there are aftermarket upgrades available for variators that can enhance their functionality and improve the performance of vehicles. These upgrades are designed to optimize power delivery, increase durability, and provide additional features. Here’s a detailed explanation of aftermarket upgrades available for variators:

1. Performance Variator Kits:

Aftermarket performance variator kits are designed to improve the overall performance of the variator. These kits often include upgraded components such as variator pulleys, sliders, and roller weights. The upgraded components are engineered to reduce friction, improve power transfer efficiency, and enhance the variator’s response. Performance variator kits can provide better acceleration, increased top speed, and improved throttle response, resulting in enhanced vehicle performance.

2. Adjustable Variator Pulleys:

Adjustable variator pulleys allow users to fine-tune the gear ratios of the variator. By adjusting the pulley positions, users can customize the variator’s performance to suit their specific needs and preferences. Adjustable variator pulleys can optimize power delivery, improve acceleration, and fine-tune the variator’s behavior for different riding conditions or modifications made to the engine. These pulleys offer increased flexibility and control over the variator’s functionality.

3. High-Performance Variator Belts:

Upgrading to high-performance variator belts can enhance the durability and power transmission capabilities of the variator. High-performance belts are designed to withstand higher temperatures and handle increased power loads. These belts often have advanced materials and construction techniques that improve their strength, flexibility, and resistance to wear. By upgrading to high-performance variator belts, users can improve the reliability and longevity of the variator, especially in high-performance or modified engine setups.

4. Variator Sliders and Roller Weights:

Aftermarket variator sliders and roller weights offer improved performance and adjustability. These components directly impact the variator’s shifting characteristics and the rate at which the gear ratios change. Upgraded sliders and roller weights can provide quicker and smoother shifts, allowing for better acceleration and improved throttle response. Additionally, aftermarket sliders and roller weights come in various weights and profiles, allowing users to fine-tune the variator’s behavior to match their riding style or specific performance requirements.

5. Variator Springs:

Aftermarket variator springs are designed to provide specific tension characteristics that can optimize the variator’s performance. Variator springs affect the rate at which the variator engages and changes gear ratios. Upgrading to aftermarket variator springs can improve launch performance, enhance low-end torque, or provide a more progressive power delivery. By selecting springs with different tension values, riders can customize the variator’s behavior to suit their riding style or desired performance characteristics.

6. Integrated Variator Tuning Modules:

Integrated variator tuning modules, often referred to as ECU or TCU (Engine Control Unit or Transmission Control Unit) tuning modules, are aftermarket devices that allow users to modify the variator’s behavior through electronic control. These modules plug into the vehicle’s electronic system and enable adjustments to various parameters such as shift points, shift speed, and shift firmness. By modifying the variator’s electronic control settings, users can enhance performance, improve throttle response, and customize the transmission behavior to match their preferences.

7. Variator Cooling Systems:

Aftermarket variator cooling systems are designed to improve the cooling efficiency of the variator. These systems often include additional cooling fins, heat sinks, or external coolers that help dissipate heat generated during operation. By improving cooling, aftermarket variator cooling systems can prevent overheating, reduce heat-related performance losses, and increase the overall durability of the variator. These upgrades are particularly beneficial for high-performance applications or when operating in extreme conditions.

In conclusion, aftermarket upgrades for variators offer a range of options to enhance their functionality and improve vehicle performance. Performance variator kits, adjustable variator pulleys, high-performance variator belts, upgraded sliders and roller weights, variator springs, integrated variator tuning modules, and variator cooling systems are some of the available upgrades. These upgrades provide opportunities to optimize power delivery, increase durability, and customize the variator’s behavior according to specific preferences or performance requirements.

Can you explain the role of a variator in continuously variable transmissions (CVTs)?

In continuously variable transmissions (CVTs), a variator plays a crucial role in providing seamless and continuous variation of the gear ratios. It is the key component that enables CVTs to offer a wide range of gear ratios without discrete gears. Here’s a detailed explanation of the role of a variator in CVTs:

A CVT is a type of transmission that can vary the gear ratio continuously within a specific range, rather than having a fixed set of gears like traditional automatic or manual transmissions. The variator in a CVT is responsible for adjusting the gear ratio based on the driving conditions and driver inputs.

The variator in a CVT typically consists of two variable-diameter pulleys connected by a belt or chain. Each pulley has a pair of adjustable sheaves that can change their effective diameter. The belt or chain runs between the two pulleys, and its position on the sheaves determines the gear ratio.

When the driver accelerates or decelerates, the variator adjusts the effective diameter of the pulleys to change the position of the belt on the sheaves. This, in turn, alters the gear ratio between the input and output shafts of the transmission. By continuously adjusting the effective diameter of the pulleys, the variator allows the CVT to provide an infinite number of gear ratios within its range.

During acceleration, the variator increases the effective diameter of the driving pulley and decreases the effective diameter of the driven pulley. This causes the belt to ride higher on the driving pulley and lower on the driven pulley, resulting in a higher gear ratio. As a result, the engine can operate at higher RPMs while the vehicle accelerates smoothly.

Conversely, during deceleration or cruising, the variator adjusts the effective diameters to lower the gear ratio. This allows the engine to operate at lower RPMs, improving fuel efficiency and reducing noise levels.

The variator continuously monitors the driving conditions and adjusts the gear ratio accordingly to provide optimal performance, whether it’s for smooth acceleration, efficient cruising, or maintaining a constant speed. The adjustments are typically controlled by a computer, which takes into account factors such as throttle position, vehicle speed, engine load, and driver inputs.

In summary, the variator in a CVT is responsible for continuously varying the gear ratio by adjusting the effective diameter of the pulleys. It allows the CVT to offer a wide range of gear ratios without discrete gears, providing smooth acceleration, improved fuel efficiency, and optimized performance in various driving conditions.

editor by CX 2024-03-15